Choosing The Right Type of Welding for Your Project

When it comes to welding, selecting the right type for your project is crucial for achieving the best results. Whether you're working on a small repair or a large industrial project, understanding the different welding techniques can help you make an informed decision. At SE-MAR Electric Company, Inc., we offer a range of welding services to meet your specific needs.

Types of Welding and Their Applications

- Shielded Metal Arc Welding (SMAW)

- Description: Also known as stick welding, SMAW is one of the most common welding methods. It uses a consumable electrode coated in flux to create an electric arc that melts the base metal and the electrode.

- Best For: Structural steel, heavy machinery, and construction projects. SMAW is versatile and can be used in various environments, including outdoor and windy conditions.

- Gas Metal Arc Welding (GMAW)

- Description: Commonly known as MIG (Metal Inert Gas) welding, GMAW uses a continuous wire electrode and a shielding gas to protect the weld from contamination.

- Best For: Thin metals, automotive repairs, and fabrication. GMAW is known for its speed and ease of use, making it ideal for high-volume production.

- Tungsten Inert Gas Welding (TIG)

- Description: TIG welding uses a non-consumable tungsten electrode and a shielding gas to create a precise and high-quality weld.

- Best For: Thin and non-ferrous metals, such as aluminum and stainless steel. TIG welding is ideal for projects that require a clean, aesthetic finish.

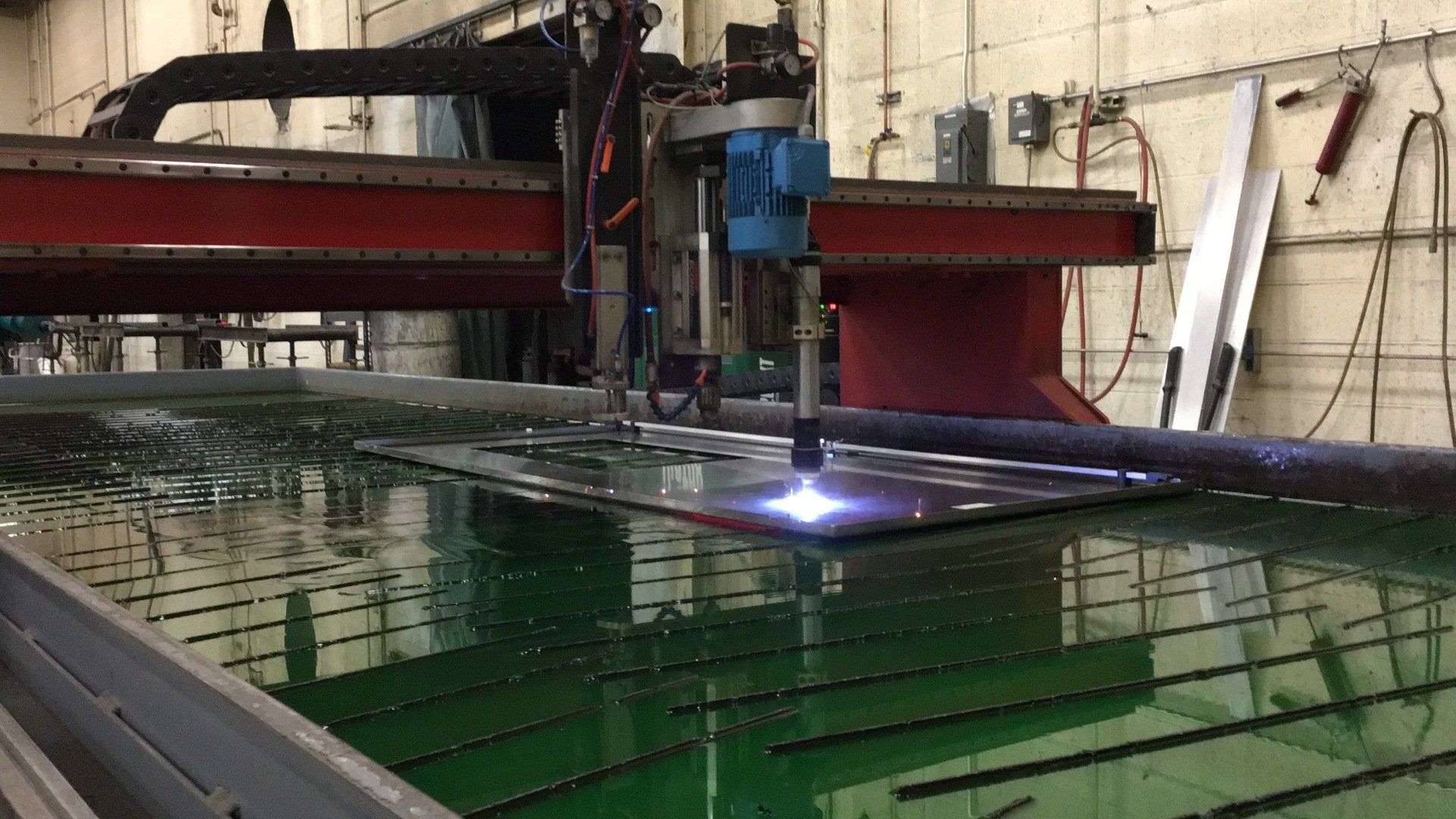

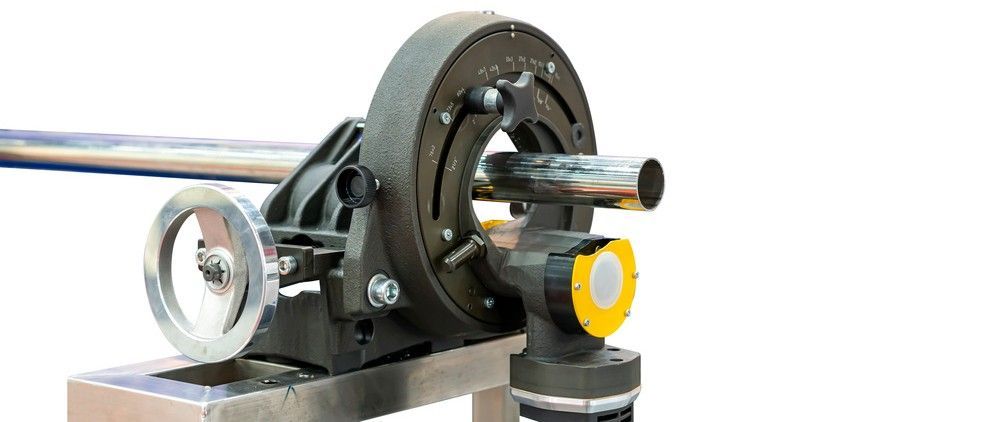

- Orbital Welding

- Description: Orbital welding is an automated process that uses a rotating tungsten electrode to create a consistent and high-quality weld.

- Best For: High-purity applications, such as pharmaceutical, semiconductor, and food processing industries. Orbital welding ensures precise and repeatable results, making it ideal for critical applications.

- Flux-Cored Arc Welding (FCAW)

- Description: Similar to MIG welding, FCAW uses a wire electrode, but the wire contains a flux core that provides additional protection and filler material.

- Best For: Thick metals, outdoor projects, and construction. FCAW is known for its ability to handle dirty or rusty surfaces and its high deposition rate.

Factors to Consider When Choosing a Welding Method

- Material Type: Different metals require different welding techniques. For example, aluminum is best suited for TIG welding, while steel can be welded using SMAW or GMAW.

- Project Size and Complexity: Large-scale projects may benefit from automated welding methods like orbital welding, while smaller projects might be better suited for manual techniques like TIG or MIG welding.

- Environmental Conditions: Outdoor projects may require welding methods that can handle wind and weather, such as SMAW or FCAW.

- Budget and Time Constraints: Some welding methods, like orbital welding, can be more expensive but offer higher precision and efficiency, which can save time and money in the long run.

Preparing for Your Welding Project

Before hiring a professional for your welding project, consider the following:

- Assess Your Needs: Determine the specific requirements of your project, including the type of metal, project size, and environmental conditions.

- Research Welding Methods: Understand the pros and cons of each welding method to choose the one that best fits your project.

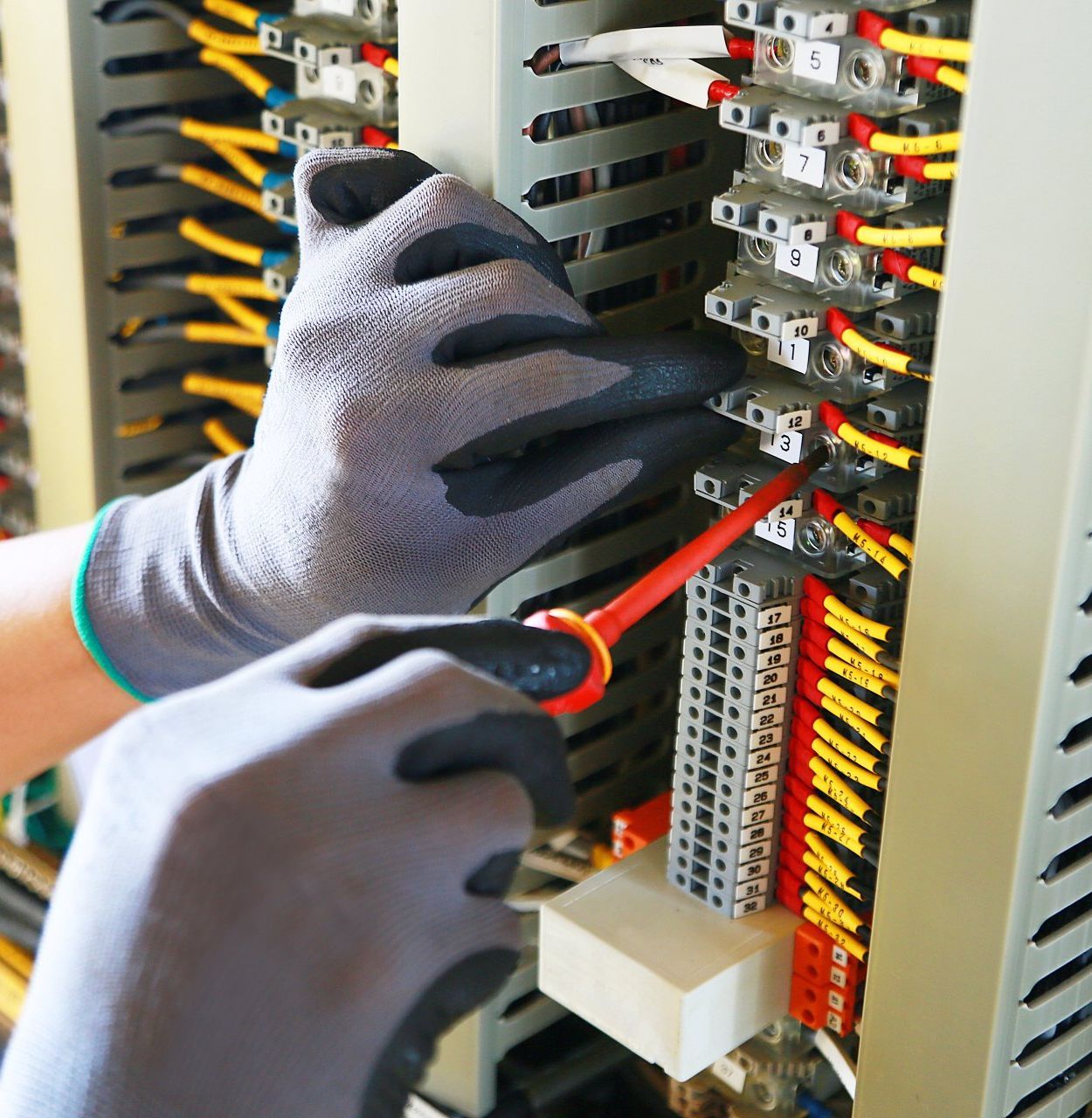

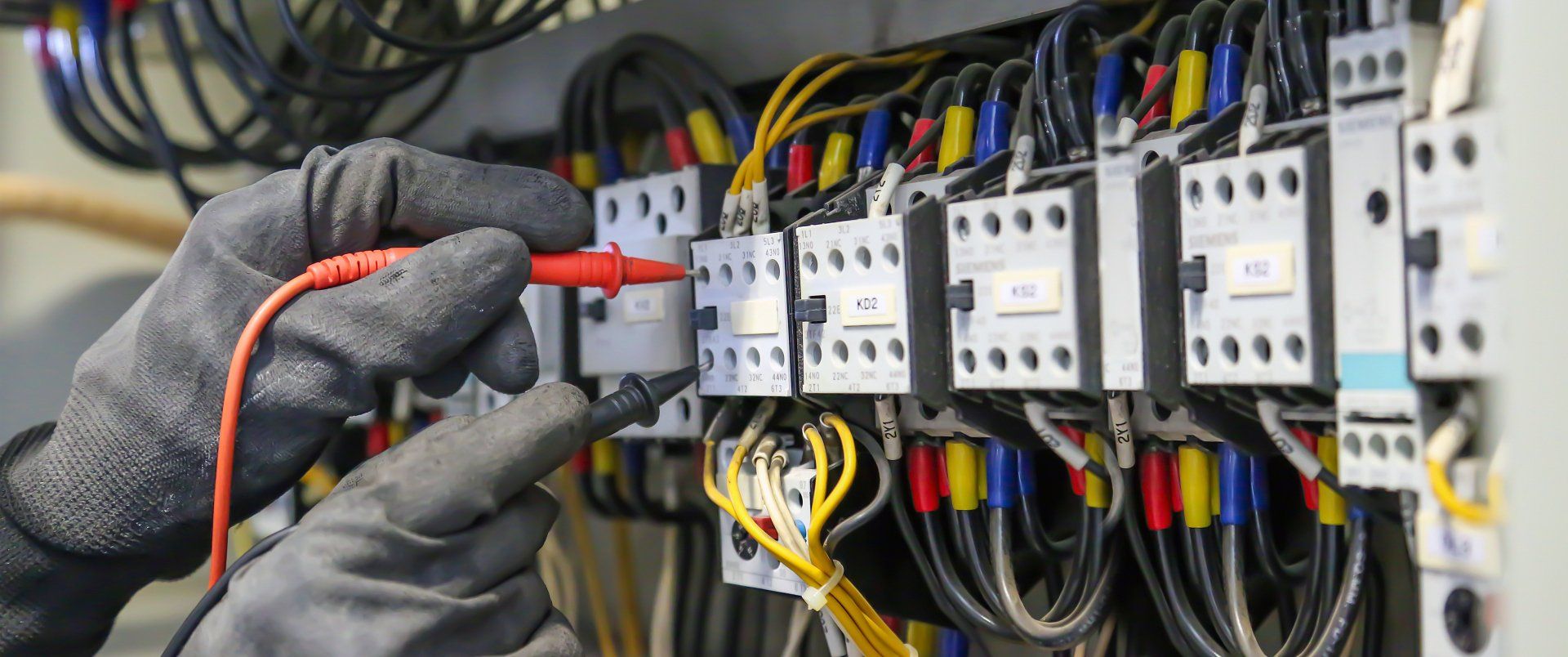

- Consult a Professional: A reliable electric company like SE-MAR Electric Company, Inc. can provide valuable advice and ensure that your project is completed to the highest standards.

Ready to Get Started?

Choosing the right type of welding for your project is essential for achieving the best results. At SE-MAR Electric Company, Inc., we offer a wide range of welding services, including orbital welding, to meet your specific needs. Our team is dedicated to providing high-quality services and ensuring your project is completed efficiently and safely.

Call SE-MAR Electric Company, Inc. at (716) 674-7404 to schedule a consultation and get a free quote. Let us help you choose the right welding method for your project and ensure its success.