How to Optimize Cable Assemblies for Industrial Efficiency

Industrial operations depend on reliable electrical connections to maintain productivity and safety standards. Cable assemblies serve as the backbone of these systems, transmitting power and data across manufacturing facilities, automation equipment, and control systems. When properly optimized, these components can improve operational efficiency while reducing maintenance costs and downtime.

Understanding how to design and maintain cable assemblies effectively requires careful consideration of environmental factors, material selection, and installation practices. The right approach can transform a standard electrical connection into a robust, long-lasting solution that supports your industrial goals.

Selecting the Right Cable Assembly Materials

The foundation of any cable assembly begins with material selection. Industrial environments present unique challenges, including temperature fluctuations, chemical exposure, vibration, and electromagnetic interference. Choosing appropriate conductor materials, insulation types, and protective jacketing directly impacts performance longevity.

Copper conductors remain the standard for most applications due to their excellent conductivity and flexibility. However, specific applications may benefit from tinned copper for enhanced corrosion resistance or aluminum conductors for weight-sensitive installations. The insulation material must withstand the operating temperature range while providing adequate electrical protection.

Consider the operating environment when selecting jacket materials. PVC offers cost-effective protection for standard applications, while polyurethane provides superior flexibility and abrasion resistance. For harsh chemical environments, fluoropolymer jackets deliver exceptional chemical resistance and temperature stability.

Proper Installation Techniques for Better Performance

Installation practices can significantly influence cable assembly performance and lifespan. Proper routing prevents unnecessary stress on conductors and connections while maintaining signal integrity. Avoid sharp bends that exceed the manufacturer's minimum bend radius specifications, as these can damage internal conductors and compromise electrical performance.

Secure cable assemblies using appropriate strain relief methods at connection points. This prevents mechanical stress from transferring to delicate terminations and reduces the risk of connection failure. Use cable ties or clamps at regular intervals to provide support without over-tightening, which can damage the cable jacket or compress internal components.

Environmental protection during installation extends cable assembly life significantly. Route cables away from heat sources, moving machinery, and areas where chemical spills might occur. When environmental hazards cannot be avoided, use additional protective conduit or cable trays to shield the assemblies.

Maintenance Strategies That Extend Service Life

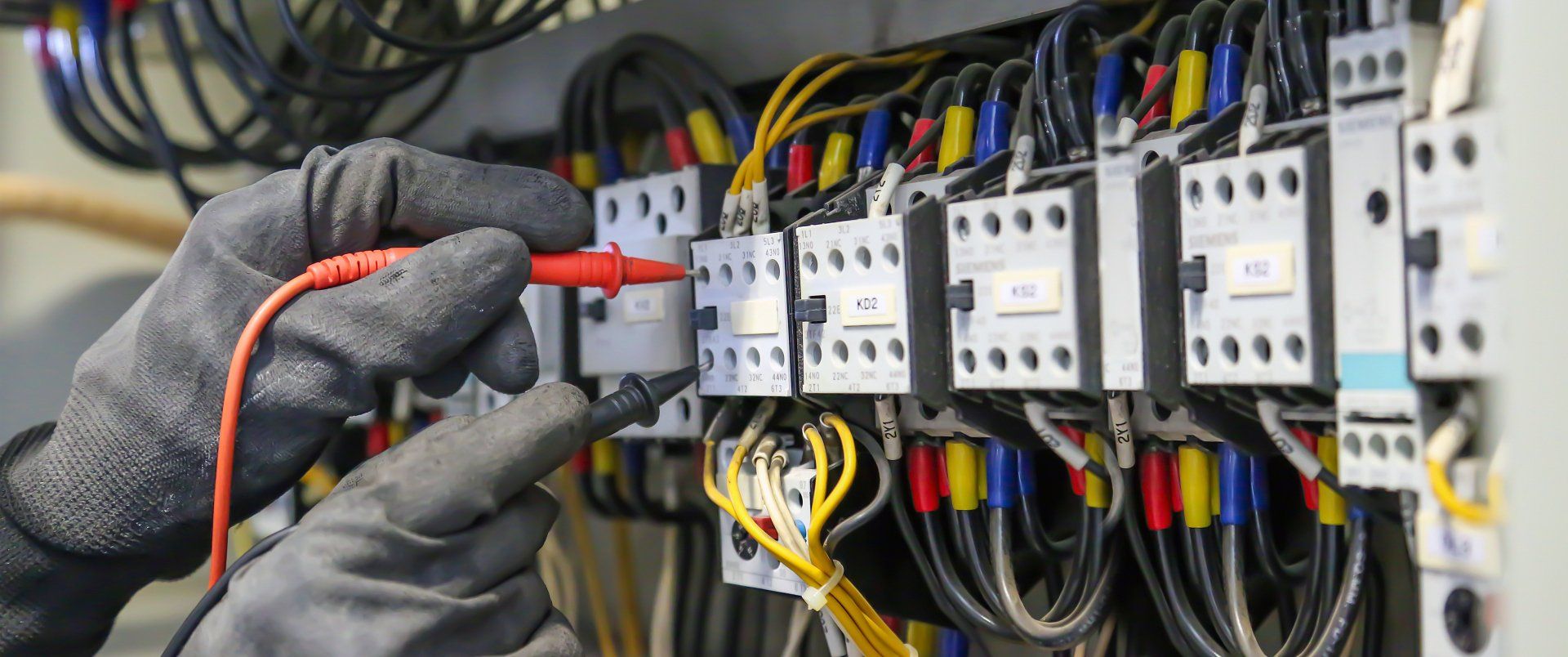

Regular maintenance schedules help identify potential issues before they cause system failures. Always keep an eye on the cable jacket integrity, connection tightness, and signs of wear or damage. Look for cracking, discoloration, or deformation that might indicate environmental stress or aging.

Electrical testing using appropriate instruments can detect performance degradation before complete failure occurs. Measure insulation resistance, continuity, and signal quality according to manufacturer specifications. Documenting test results and tracking performance trends over time can help you predict when a replacement might be necessary.

Environmental monitoring helps optimize maintenance intervals and identify conditions that accelerate cable assembly degradation. Track temperature cycles, humidity levels, and exposure to chemicals or contaminants that might affect performance. This data enables proactive maintenance scheduling and informed decisions about cable assembly specifications for future installations.

Contact us for Reliable Cable Assembly

Selecting the right manufacturing partner is crucial for achieving optimal cable assembly performance in industrial applications. At SE-MAR Electric Company, Inc., we specialize in providing high-quality cable assemblies designed to meet demanding industrial requirements. Our experienced team understands the unique challenges faced by industrial operations and can recommend solutions that maximize efficiency and reliability.

When you need cable assemblies that deliver consistent performance in challenging environments,

contact us to discuss your needs. Our commitment to quality manufacturing and customer service ensures your industrial operations maintain peak efficiency with reliable electrical connections you can trust.