The Advantages of Cable Assemblies in Industrial Facilities

When it comes to powering and maintaining industrial facilities, the quality and organization of wiring systems are critical. Cable assemblies play an integral role in meeting the high demands of industrial environments while ensuring efficiency and reliability. These pre-assembled, ready-to-use cable systems are engineered to keep operations running smoothly. For facilities looking to optimize performance, reduce costs, and enhance safety, cable assemblies are a game-changer.

What Are Cable Assemblies?

Cable assemblies consist of multiple wires or cables bundled together into a single, organized unit, often encased in durable protective materials. These assemblies are pre-manufactured to meet specific requirements, meaning they’re custom designed for particular applications or systems. Whether it’s providing power for machinery or transmitting data, cable assemblies are key to streamlining complex wiring systems in industrial settings.

Benefits of Cable Assemblies in Industrial Facilities

1. Improved Efficiency

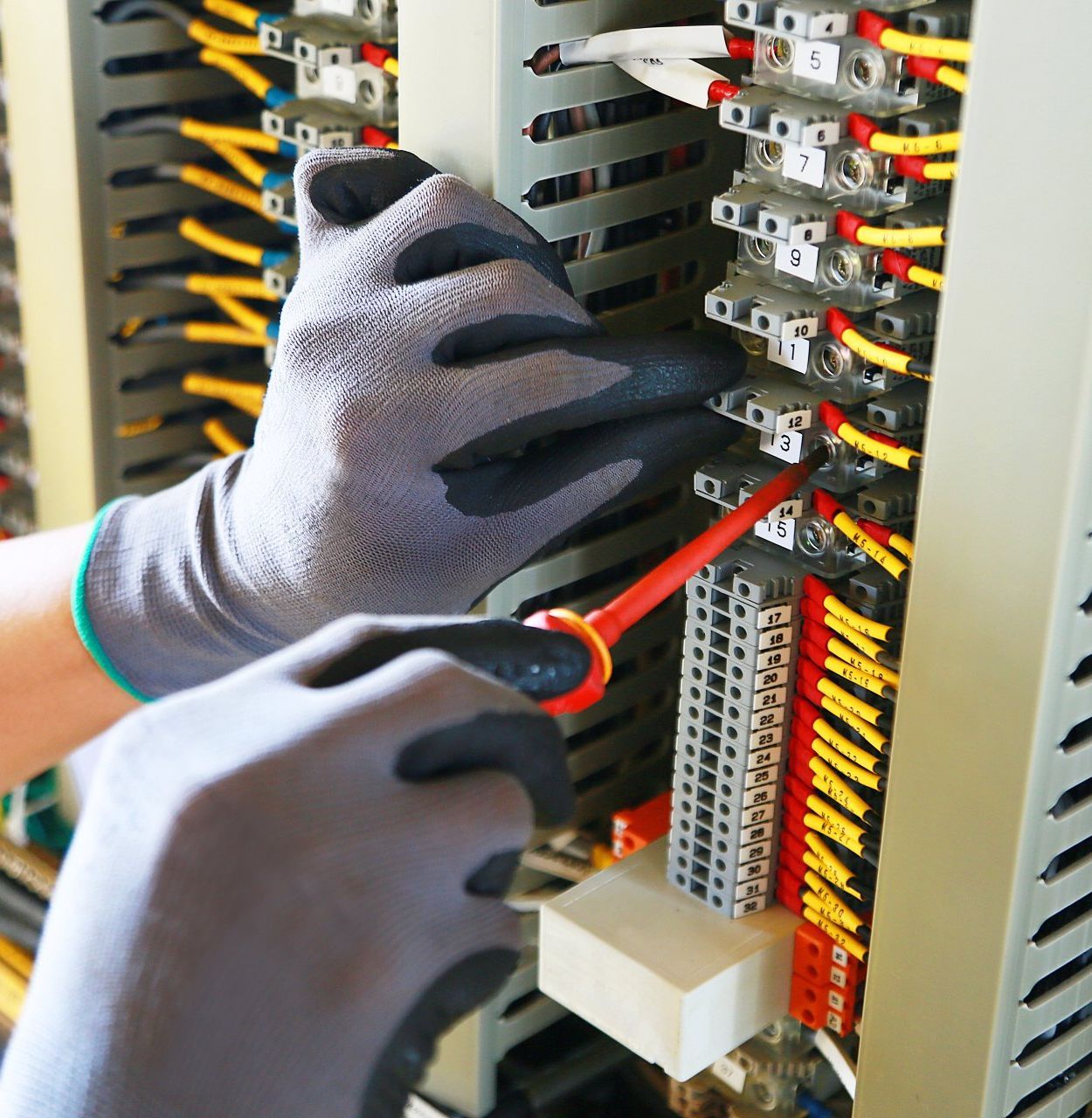

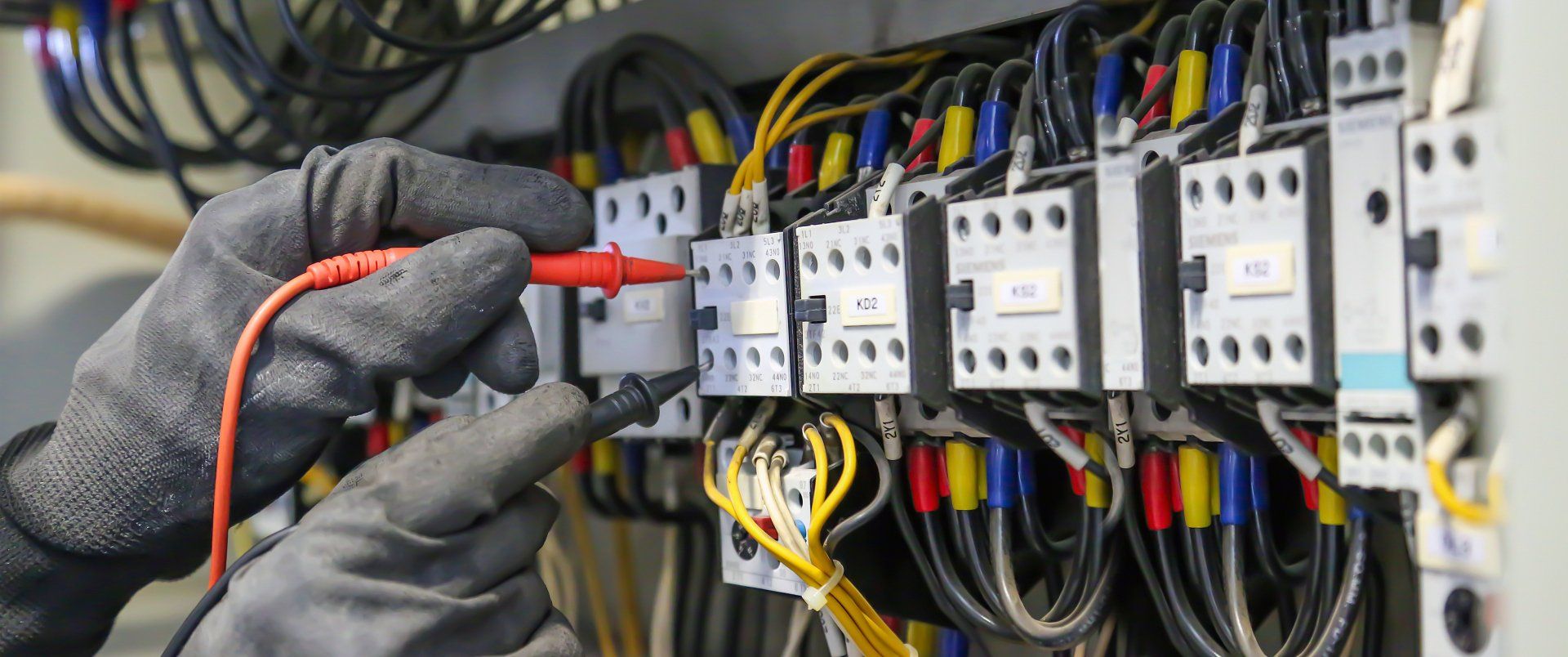

Industrial facilities often rely on complex wiring systems that link various pieces of equipment and machinery. Managing these systems manually can be time-consuming and error-prone. With cable assemblies, you gain a pre-organized solution that reduces installation time. These assemblies come with precisely labeled connections and standardized layouts, enabling quick and easy setup or reconfigurations. Efficiency extends beyond installation. Cable assemblies also simplify troubleshooting and repairs. When equipment fails in industrial environments, minimizing downtime is crucial. Pre-assembled cables allow technicians to identify and address issues faster, getting systems back online without unnecessary delays.

2. Enhanced Safety

Safety is a top priority in industrial facilities, where high voltage, heavy machinery, and rough conditions present ongoing risks. Poorly organized wiring can not only compromise operational performance but also lead to dangerous electrical hazards. Cable assemblies provide a clean, organized layout that reduces the risk of loose or stray wires causing malfunctions or accidents. The protective materials surrounding the wires shield them from environmental factors like heat, moisture, vibration, or chemical exposure. This added durability ensures safe and consistent performance, even in demanding conditions. Additionally, many cable assemblies are designed to meet strict industry safety standards, offering peace of mind for facility managers and workers alike.

3. Cost-Effectiveness

Investing in cable assemblies may seem like an upfront expense, but their long-term benefits significantly outweigh the costs. By reducing installation and maintenance time, facilities lower their operating expenses. Additionally, the streamlined wiring provided by these assemblies helps prevent costly mistakes during installation or maintenance.

Cable assemblies are also highly durable, reducing wear and tear and the need for frequent replacements. Facilities can enjoy long-lasting wiring solutions that stand the test of time, minimizing repair costs and improving overall ROI.

4. Reliability in Demanding Environments

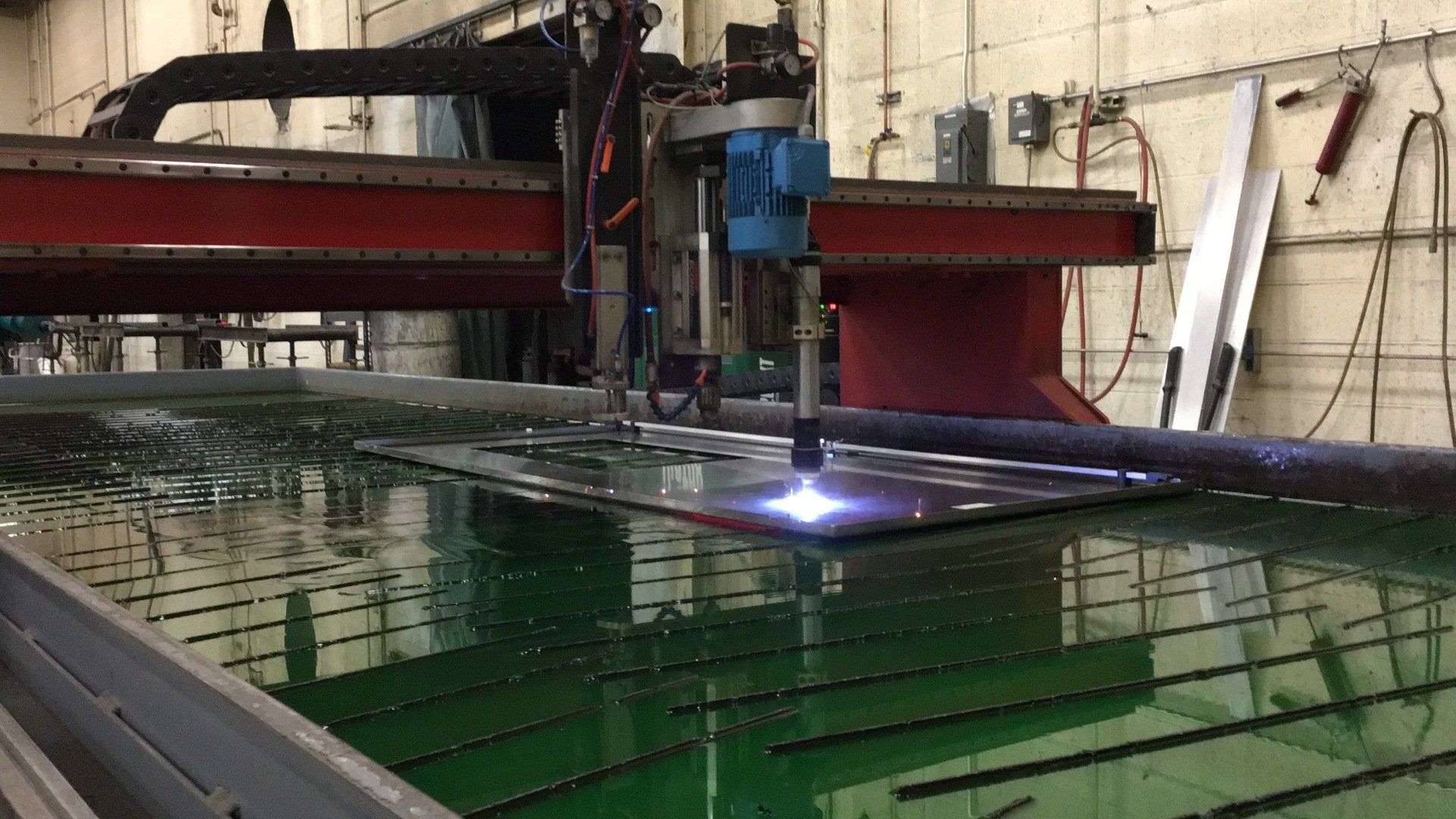

Industrial facilities operate under some of the harshest conditions, and reliable performance is non-negotiable. Cable assemblies are designed to perform under stress, whether it’s in environments with extreme temperatures, constant vibrations, or heavy exposure to pollutants.

By using high-quality materials and innovative design techniques, cable assemblies ensure uninterrupted power, data transmission, and functionality for critical industrial systems. This reliability is essential for maintaining productivity and avoiding costly interruptions in operations.

5. Reduced Downtime

Unexpected equipment failure can lead to significant downtime in industrial settings, affecting production schedules and profits. Cable assemblies are engineered to minimize disruptions by offering durable, pre-tested solutions tailored to your facility’s needs.

Pre-assembled and quality-checked cables allow for quick replacements or upgrades, ensuring minimal impact on your operations. Furthermore, their streamlined design reduces the likelihood of recurring issues caused by poor wiring or environmental factors.

Applications of Cable Assemblies in Industrial Facilities

Cable assemblies are versatile and can be used across a range of industrial applications, including:

- Automation Systems: Supporting seamless and accurate data transmission for automated equipment.

- Machinery: Powering heavy-duty equipment reliably and safely.

- Conveyor Systems: Managing wiring for extensive conveyor networks with ease.

- Data Centers: Simplifying cable management for high-performance computing systems.

Contact SE-MAR Electric Company, Inc Today

Thinking about integrating cable assemblies into your industrial facility? Contact SE-MAR Electric Company, Inc. to learn how we can help you enhance efficiency, improve safety, and save costs with our expertly designed solutions. Optimize your facility with cable assemblies that meet the demands of today’s complex industrial environments. Call us today to get started!