What is Orbital Welding?

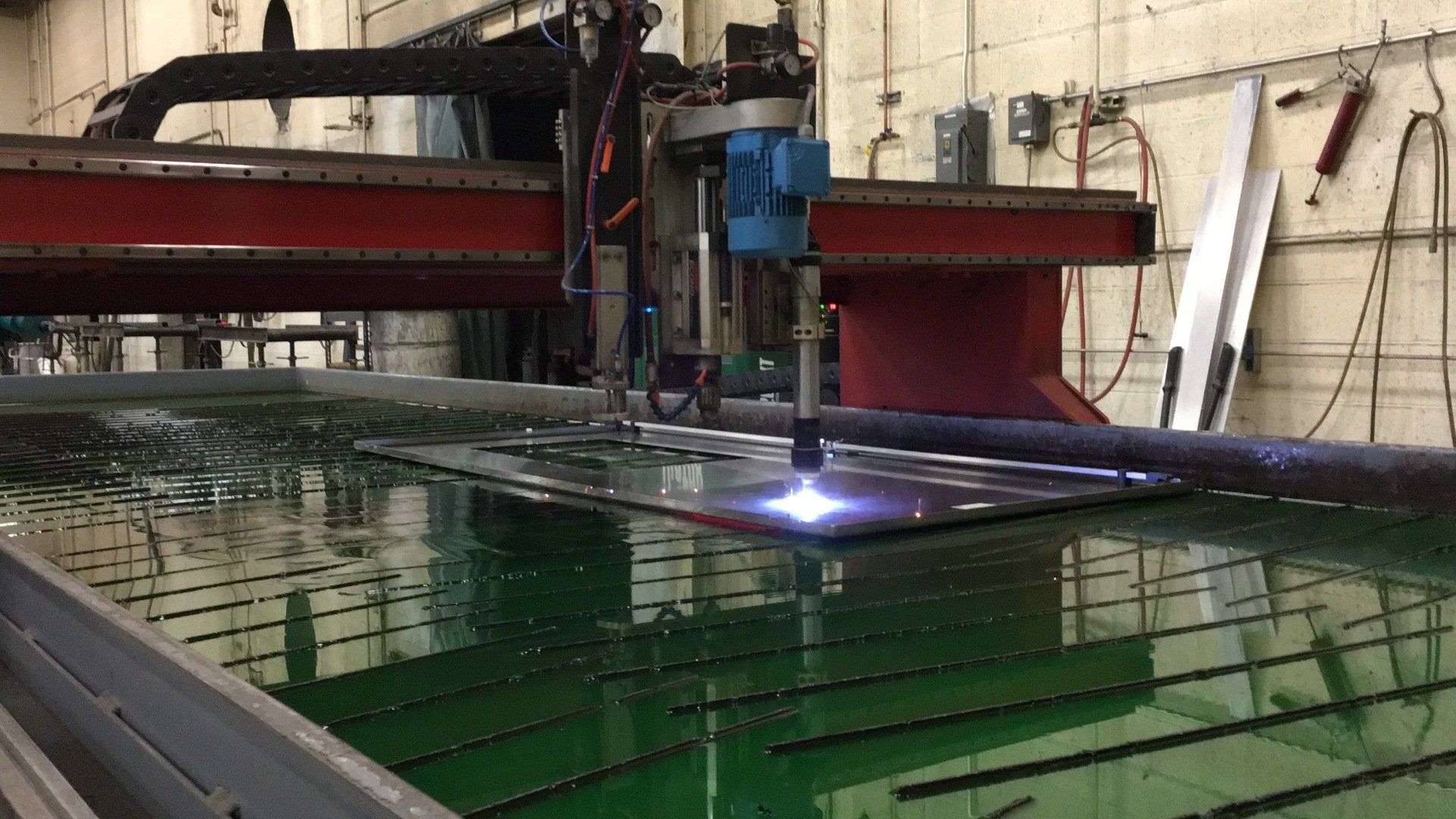

Orbital welding is a specialized technique that was developed by Rodrick Rohrberg in order to fix hydraulic fluid leaks for planes. Since then, the technique has been used in multiple industries to solve the problem of errors that would occur when attempting to weld cylindrical parts.

Instead of manually welding the pieces together, orbital welding uses a mechanized welding head and wire system to weld at 360 degrees, allowing for optimal results repeatedly. This provides multiple benefits, including:

- Reduced Error Rate: With the mechanized aspects of this technique, there is a decreased chance of error in the welding process that can result in poor penetration and poor or inconsistent fusion.

- Improve Workflow: With the assistance of orbital welding, industrial engineers’ workflow can speed up without jeopardizing the quality of the results, allowing them to spend the saved time on other important tasks.

- Versatility: Orbital welding is useful in several industries, including biotechnology, pharmaceutical, electronics, aerospace, chemical and nuclear piping and more. This welding technique also has multiple applications for sanitary tubing, piping, overlay and more.

Contact Our Electric Company to Learn More!

SE_MAR Electric Company, Inc. performs orbital welding and other industrial engineering services. Orbital welding is an ideal technique that can be performed even in restrictive environments with consistent results. From contemporary control panel design and custom control panels to process tubing and rectifier power supplies, our technicians are here to provide quality industrial engineering manufacturing services and products. Contact us today to learn more!