Which Type of Control Panel is Right for Your Operation?

Selecting the right control panel for your operation is more than just a practical decision; it’s a strategic move that can streamline processes, increase efficiency, and ensure safety. Whether you’re in manufacturing, energy, healthcare, or any other industry, understanding the principles of control panel design and tailoring your system to your unique needs is critical for success. But with so many types of control panels available, how do you determine which one is right for you?

To choose the right control panel, you have to consider the specific options available to you, specifically the key considerations that go into control panel design and the benefits of choosing an expert to support your operations. Learn more about the different control panel options available to you and which would be the best for your business.

The Importance of the Right Control Panel

Control panels serve as the heart of your operation, integrating commands, processes, and feedback loops into one cohesive system. They manage everything from monitoring equipment to triggering operational sequences, all while providing critical data for decision-making. The right control panel design ensures reliable performance and optimizes production, while a misaligned panel could lead to downtime, inefficiencies, or even safety risks. It's essential to choose a control panel that is tailored to your organization's needs.

Types of Control Panels and Their Applications

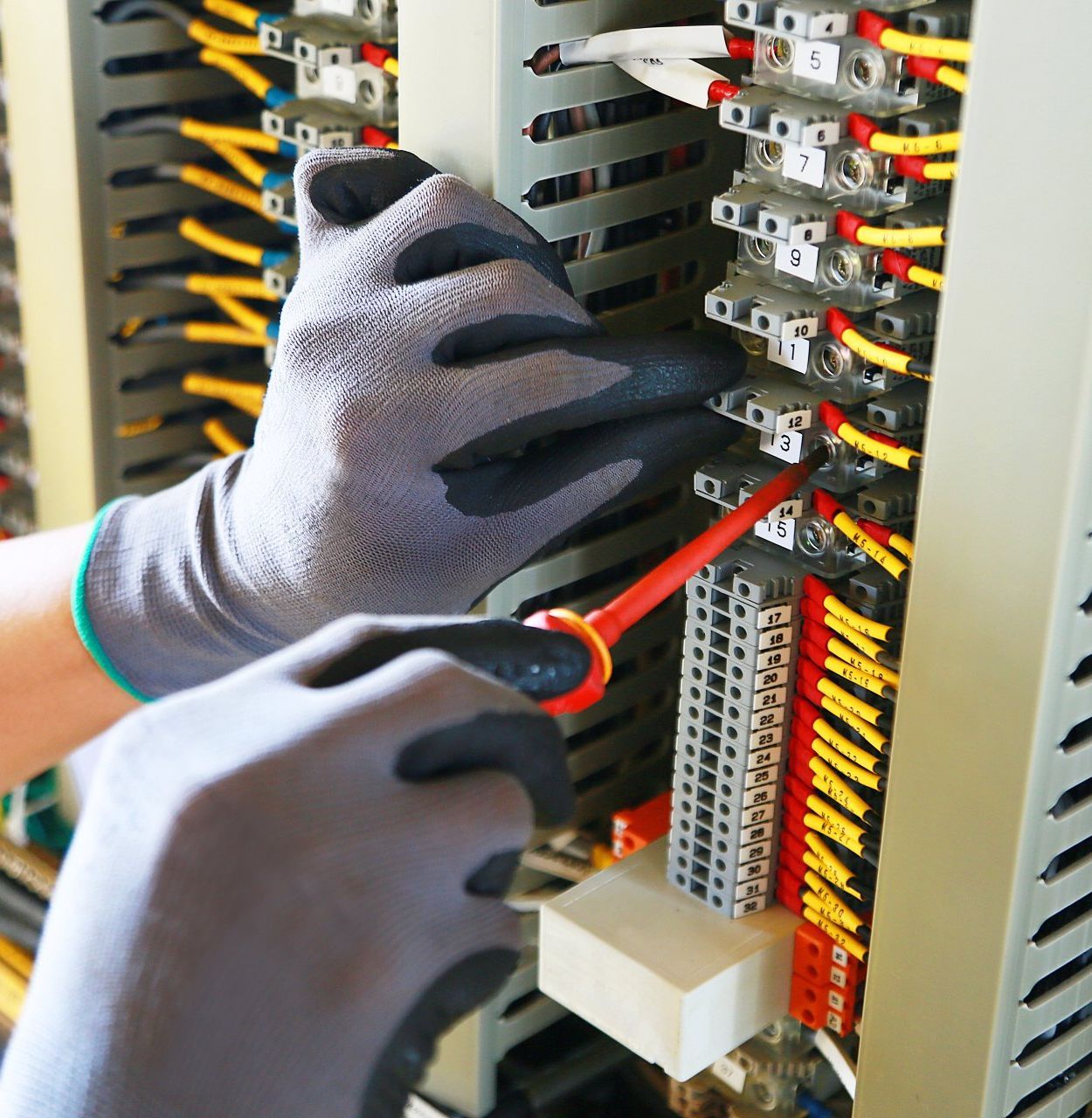

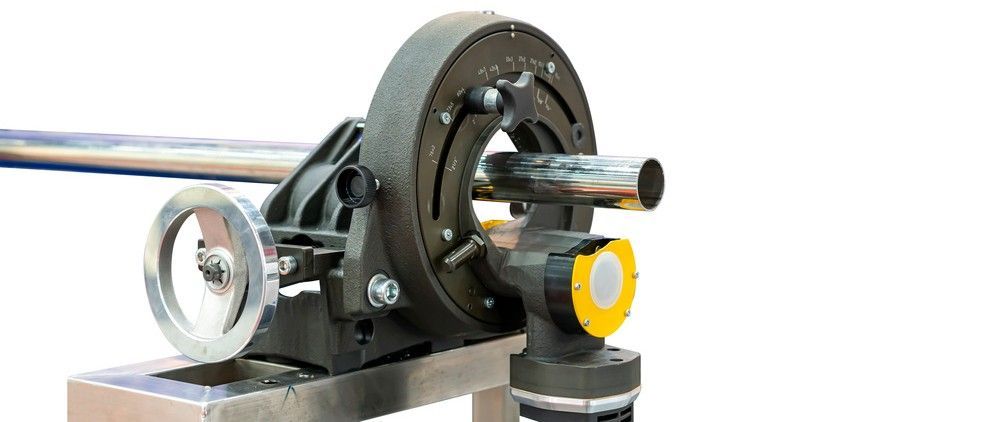

1. Motor Control Panels

Motor control panels are designed to start, stop, and regulate motors used in various industries like manufacturing and HVAC. They often integrate variable frequency drives (VFDs), soft starters, and remote monitoring capabilities, making them ideal for operations that require precise motor management. An example would be the motor control panels used to operate conveyor belts that transport materials in a factory.

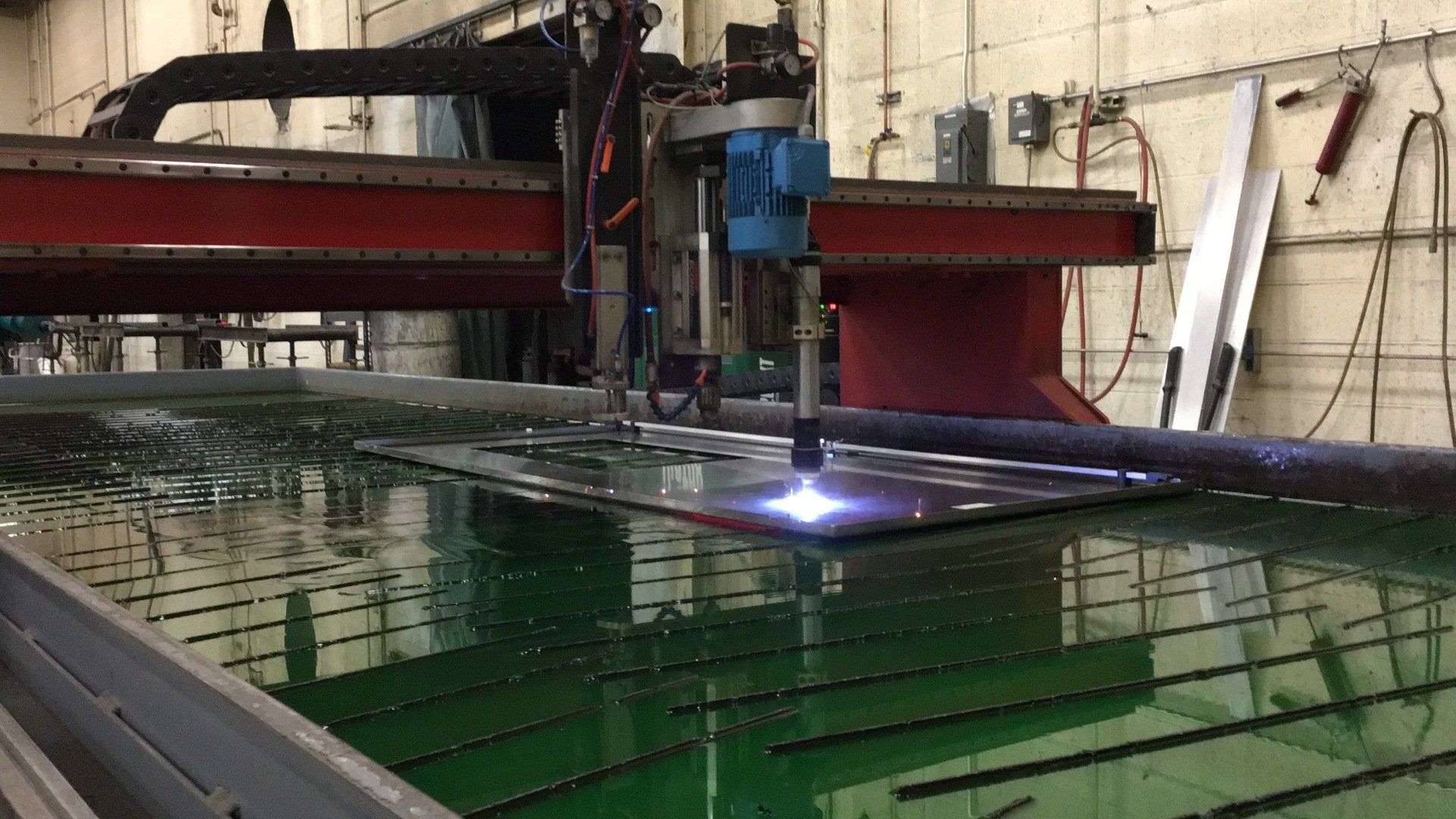

2. Automation Control Panels

Automation control panels combine programmable logic controllers (PLCs), human-machine interfaces (HMIs), and other components to automate complex processes. They’re highly customizable and often used in industries like food processing or pharmaceuticals, where precision and scalability are critical. Automation control panels are used on beverage production lines to to manage filling, capping, and labeling machines, all while maintaining high-volume output.

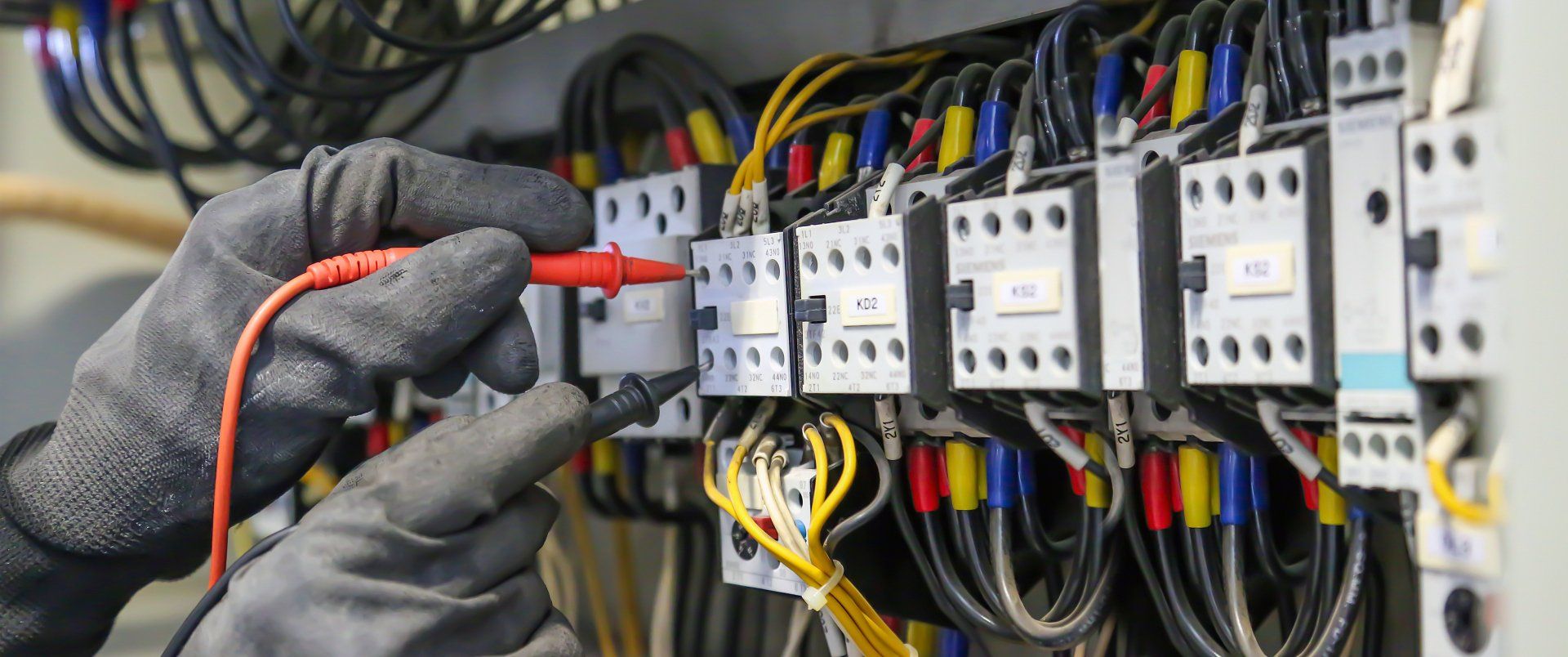

3. Power Distribution Panels

These panels distribute electricity efficiently and safely across a facility. They’re essential in large-scale operations, such as data centers or industrial plants, where uninterrupted power is crucial. Renewable energy facilities use power distribution panels to manage the flow of electricity generated by solar panels and distribute it across the grid.

4. Lighting Control Panels

Lighting control panels are designed to manage a facility’s lighting system, improving energy efficiency and reducing operational costs. Smart lighting control options are becoming popular in commercial and residential settings alike. Lighting control panels are used in warehouses to automate LED lights, making sure to dim the lights or turn them off entirely in unused areas.

5. Custom Control Panels

For operations with highly specific requirements, custom control panels can be designed from the ground up. These panels integrate all necessary components to meet specialized needs, ensuring optimal performance. A biotech lab might require a custom control panel to coordinate and monitor multiple high-precision processes simultaneously.

Key Factors to Consider in Control Panel Design

When it comes to choosing the right control panel for your operation, a well-thought-out design makes all the difference. Here are the key considerations:

- Operational Needs: Start by analyzing your operation’s specific requirements. What processes need to be controlled? Will the panel operate in a harsh environment? Answering these questions will help narrow down the type of panel that will work best for you.

- Compliance and Safety Standards: Adherence to industry regulations and standards is crucial to ensure safety and legality. Compliance also influences panel reliability and reduces potential risks during operation.

- Scalability: Is your business expecting growth? Investing in a scalable control panel design now can save costs later, as you’ll have the flexibility to expand operations without overhauling your system.

- Space Constraints: The physical layout of your facility may dictate the panel's size, shape, or mounting options. Compact designs can be more advantageous in space-limited environments.

- Integration Capabilities: Modern control panels often need to integrate with existing systems. Ensuring compatibility and seamless communication between your control panel and other systems is vital for long-term success.

- User Interface: Whether it’s an operator on the floor or a technician performing maintenance, clear and intuitive controls simplify usage and minimize errors.

Contact SE-MAR Electric Company, Inc Today to Choose the Right Control Panel for Your Operation

Selecting the right type of control panel begins with understanding your unique operational challenges. By carefully evaluating factors like functionality, compliance, and scalability, you can choose a system that supports your goals while optimizing performance. Whether you need a motor control panel for a manufacturing facility, an automation control panel for precision tasks, or a custom solution tailored to highly specific needs, a well-designed panel will keep your operations running smoothly.

Partner with the experts at SE-MAR Electric Company, Inc. to help you understand what kind of control panel you need for your operation. Never underestimate the importance of control panel design. SE-MAR Electric Company, Inc. can help you enhance your operation's overall efficiency and help your operation evolve to meet future demands. With SE-MAR Electric Company, Inc., you'll be working with a team that prioritizes quality and innovation. Let us assist with custom control panels and control panel design that will help your business have success.