How to Maintain Your Electrical Systems During Summer Heat

Summer heat can be relentless, and industrial electrical systems often bear the brunt of extreme temperatures. Overheating can lead to equipment failure, downtime, and skyrocketing maintenance costs. However, with proactive measures and diligent care, you can keep your systems running smoothly, even during the hottest months of the year. Keep in mind these valuable tips for maintaining industrial electrical systems under high temperatures, ensuring safety, efficiency, and reliability.

Understanding the Risks of Overheating

Before diving into maintenance strategies, it’s crucial to understand why heat poses such a threat to electrical systems. Prolonged exposure to high temperatures can degrade wires, reduce the efficiency of circuits, and lead to the overheating of transformers, motors, and other sensitive components. Overheating may also result in unplanned downtime, equipment damage, or safety hazards like electrical fires. Fortunately, these risks can be minimized through proper preventive care.

Essential Tips for Maintaining Electrical Systems

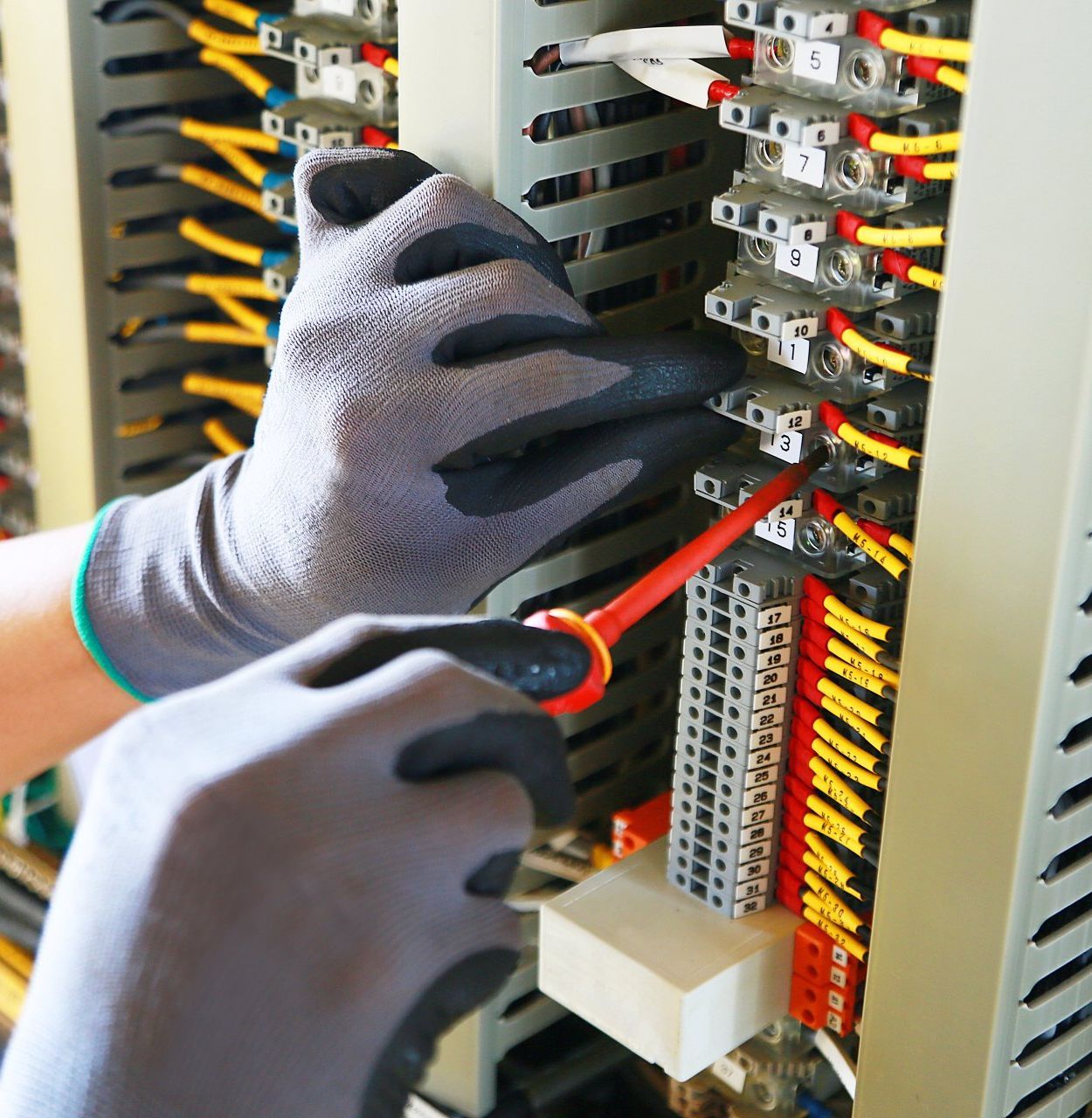

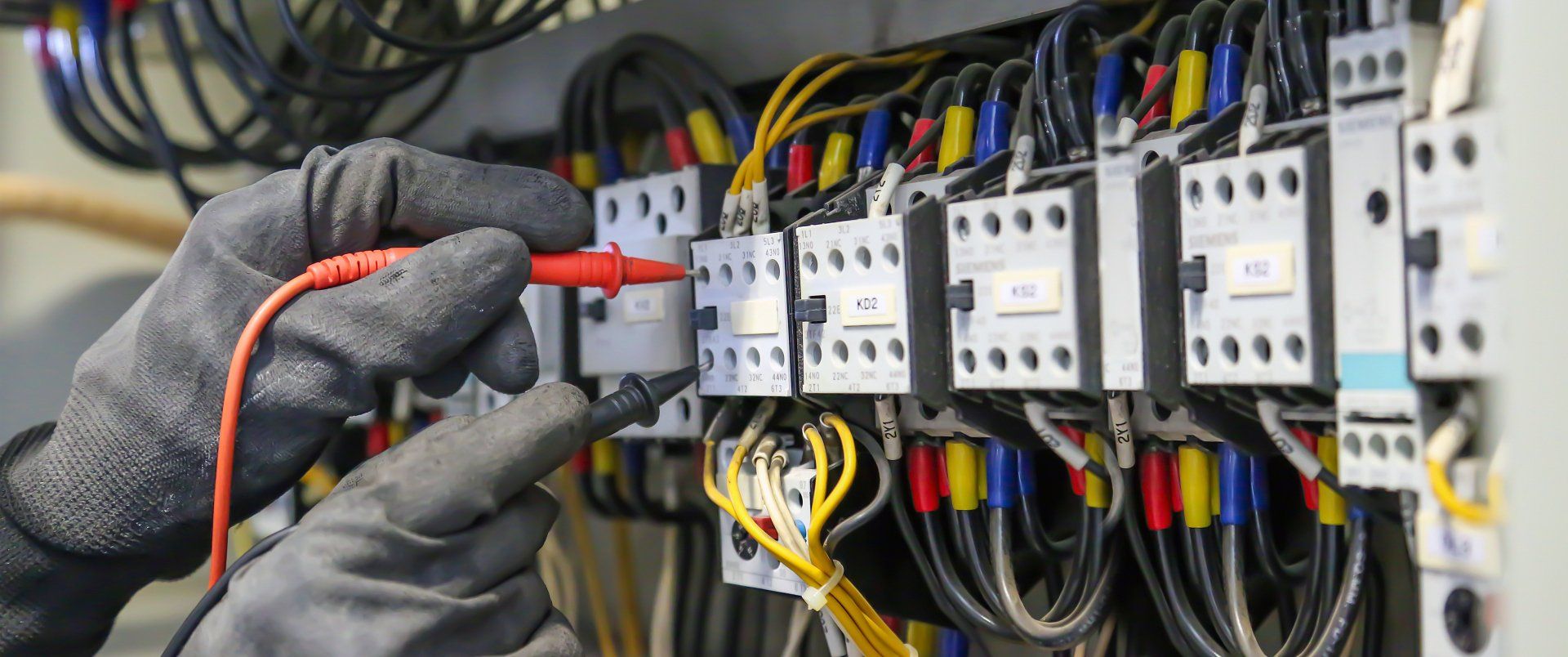

1. Conduct Regular Inspections

Performing routine maintenance checks is critical during summer. Schedule inspections of all electrical components, including transformers, circuit breakers, and wiring. Look for any signs of wear, such as melted insulation, discoloration, or loose connections. Early detection of small issues can prevent larger, more expensive problems down the line.

2. Ensure Proper Ventilation

Heat buildup can severely strain your electrical systems. Ensuring proper airflow and ventilation can help regulate temperatures and minimize stress on your equipment. Clean cooling fans, vents, and air filters regularly to prevent blockages and ensure efficient heat dissipation. If your equipment is housed indoors, consider installing or upgrading HVAC systems designed for industrial settings. Maintaining an optimal ambient temperature protects sensitive gear from overheating, particularly in enclosed spaces where heat can accumulate quickly.

3. Monitor and Manage Electrical Loads

Overloading circuits during peak operation hours can exacerbate overheating issues, especially in summer when cooling systems may already be working hard. Review your facility’s electrical load distribution and ensure circuits aren’t carrying more capacity than they’re rated for. Consider staggering energy-intensive operations during off-peak hours to reduce strain. Using a load management system can help monitor and balance power consumption across all equipment efficiently.

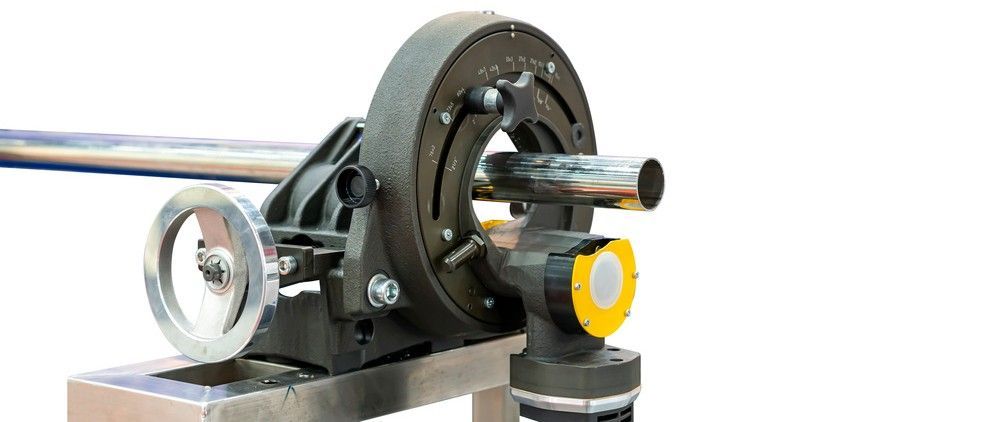

4. Inspect Cooling and Lubrication Systems

For equipment that relies on cooling or lubrication, such as motors and transformers, summer is the time to prioritize maintenance. Check coolant levels and ensure all pumps are functioning properly. Insufficient cooling or lubrication could lead to increased friction, which can exacerbate overheating and wear. Make sure to replace worn-out parts or fluids promptly to keep your machines running at peak efficiency.

5. Focus on Preventive Maintenance

Preventive maintenance is the backbone of a well-functioning electrical system. Create a summer-specific checklist that prioritizes heat-related risks, including testing circuit breakers, tightening loose connections, and cleaning components prone to dust accumulation. Partnering with licensed electricians to conduct periodic maintenance ensures adherence to safety standards and enhances the performance of your facility’s electrical infrastructure.

6. Upgrade Outdated Equipment

Older electrical systems may struggle to cope with high temperatures, especially if components are nearing the end of their lifespan. Consider upgrading outdated systems or replacing parts that have become inefficient. Modern equipment is typically built with better insulation and heat resistance, reducing the risk of overheating. Energy-efficient upgrades can also reduce power consumption and improve overall system reliability, saving you money in the long run.

7. Prepare for Emergencies

Despite your best efforts, unexpected issues can still arise during extreme heat. Make sure you have an emergency response plan in place to minimize downtime and protect your facility. Equip your team with proper training and ensure they know how to handle overheating situations or electrical failures safely. Keep key contact information for local electricians, utility providers, and safety inspectors readily available. A quick response can make all the difference in preventing small problems from turning into major disasters.

Benefits of Proactive Maintenance

Taking these proactive steps not only helps your equipment withstand the summer heat but also delivers long-term benefits, such as:

- Reduced Downtime: Addressing minor issues before they escalate avoids costly interruptions to your operations.

- Improved Safety: Proper maintenance reduces the risk of electrical fires and other safety hazards.

- Enhanced Efficiency: Clean, well-maintained systems operate more reliably and consume less energy.

- Cost Savings: Preventive care is significantly less expensive than emergency repairs or complete equipment replacements.

Contact SE-MAR Electric Company, Inc for Electrical Engineering Services

Maintaining your industrial electrical systems during the summer heat requires a combination of vigilance, regular maintenance, and strategic upgrades. By following the tips outlined here, you can protect your systems from overheating, ensure uninterrupted operations, and save on unnecessary costs.

Partnering with the experienced professionals at SE-MAR Electric Company, Inc. can help you implement an effective maintenance plan tailored to your facility’s unique needs. Don’t wait for the heat to take a toll on your systems—start preparing today for a smooth, efficient summer season. Trust SE-MAR Electric Company, Inc. to help you maintain your electrical systems during summer heat. Based in West Seneca, NY, we are an industry leader when it comes to industrial electrical manufacturing, industrial engineering, and custom control panels. Contact our designers today to learn more about how to take care of your electrical systems.