Process Skids: Streamlining Processes

Businesses can always benefit from streamlining their processes. It can do things like reduce production times, improve quality, and lower the cost of production. Many methods can be used to streamline processes including process skids. Process skids can help streamline industrial processes which allows you to boost productivity. So, what are process skids? Below, we will discuss what they are and how they can impact your business.

What are Process Skids?

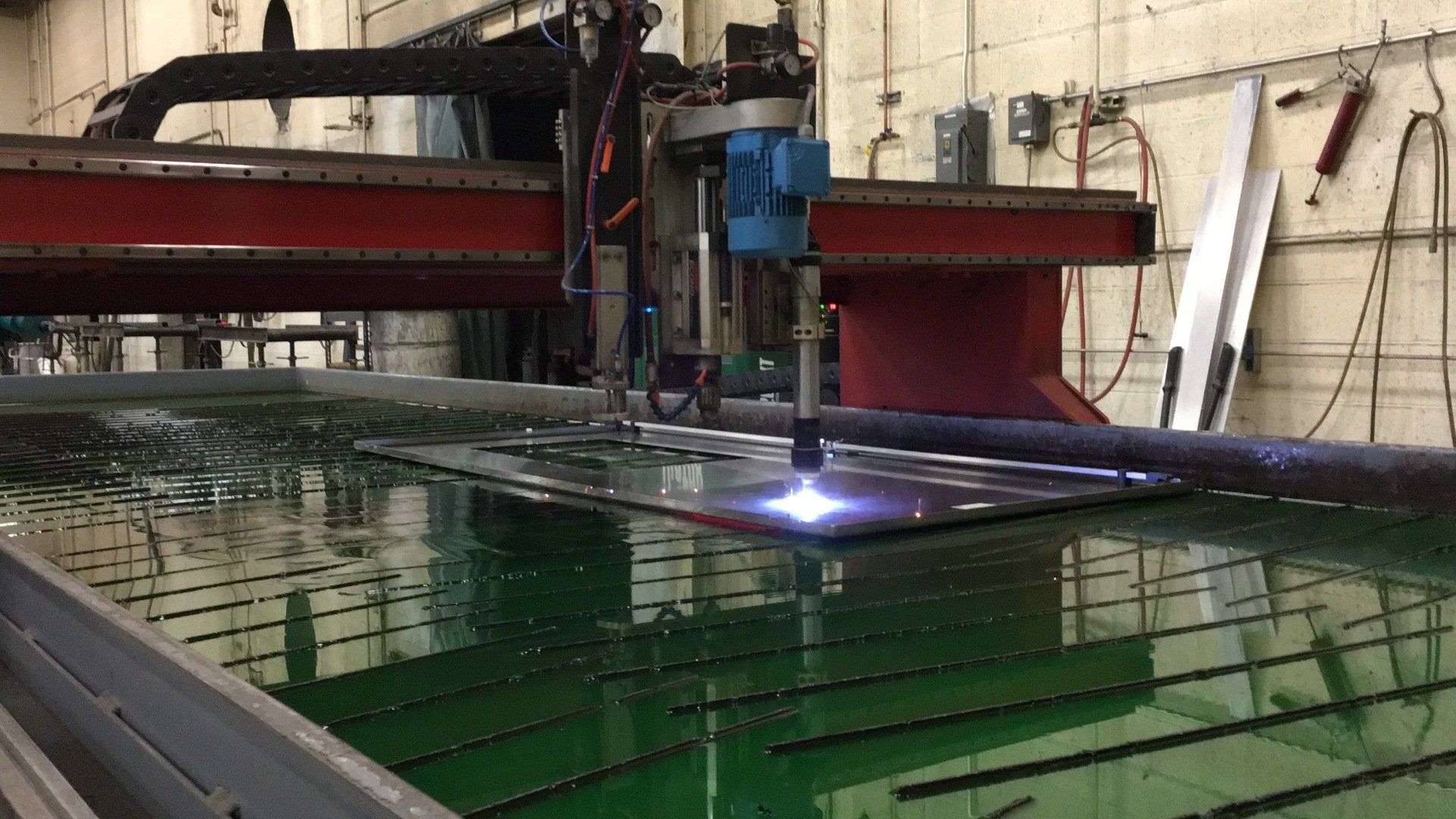

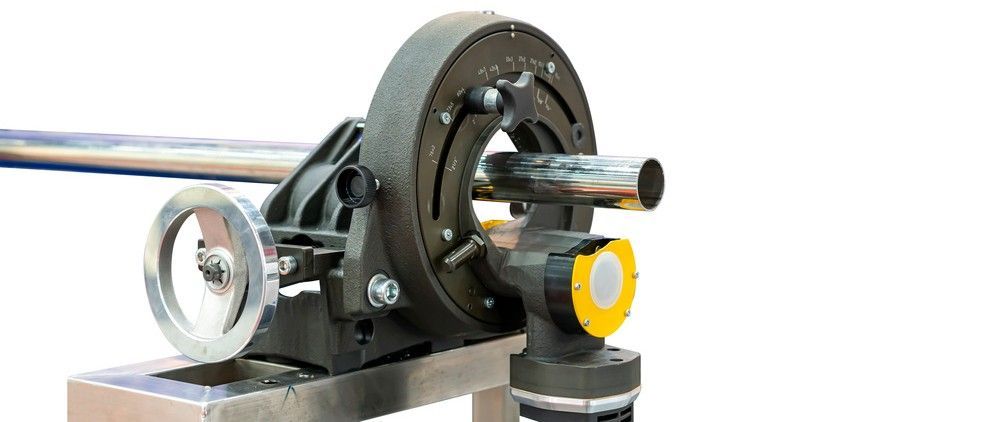

Process skids, also known as modular process systems or packaged systems, are self-contained units that have multiple components that are used for an industrial process that are contained on a single skid. Skids are built and tested off-site to ensure they function properly. They can then be transported to the desired location.

Process skids are customized to meet the specific requirements of each industrial process. Common components that can be found on a skid include pumps, filters, control systems, piping, heat exchangers, valves, and other instruments. All components are carefully selected for optimal functionality while minimizing space requirements.

Advantages of Process Skids

Time and Cost Savings: Process skids are pre-engineered and pre-fabricated, reducing the time and cost associated with on-site construction. They can be manufactured concurrently with site preparation, resulting in faster project completion and reduced labor costs.

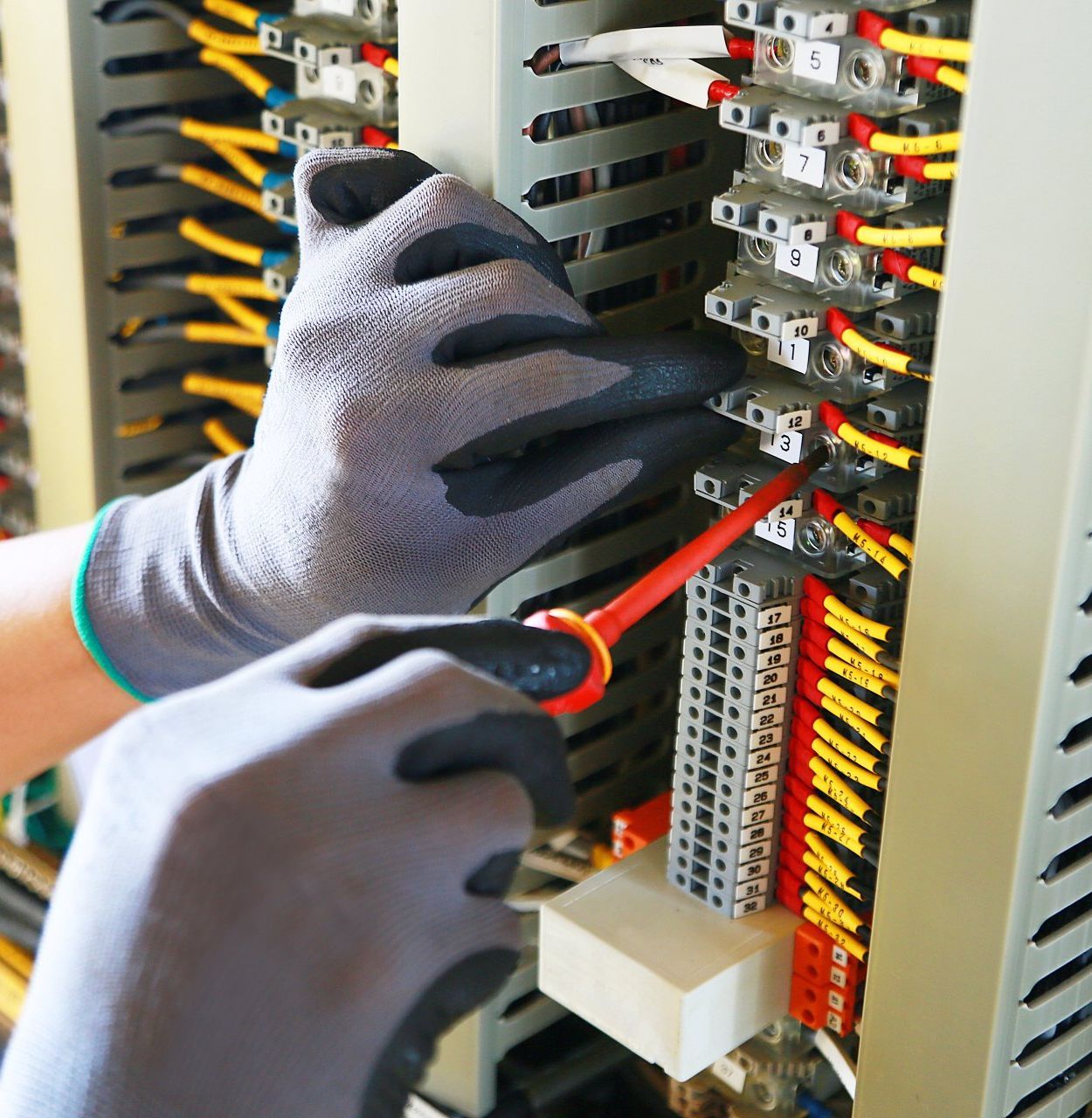

Quality Control: Process skids are built in controlled environments and undergo rigorous testing during their fabrication. This allows us to ensure that there are no defects with the skid, and it meets all industry standards.

Flexibility and Scalability: Process skids offer flexibility in terms of design and scalability. They can be easily modified or expanded to accommodate changing process requirements or increased production capacity. This adaptability allows you to change your skids to meet your ever-changing needs.

Safety and Reliability: Safety is always our number one priority. Just like you, we never want someone to get injured while using a process skid. Our engineers rigorously test all components of the skid to ensure that they function properly during usage. The testing also helps to minimize the possibility of leaks, spills, or accidents.

Ease of Maintenance: Process skids are designed for easy access and maintenance. Components can be easily inspected, repaired, or replaced without disrupting the entire process. This reduces downtime and improves overall operational efficiency.

Contact Us Today for Custom Process Skids!

At SE-MAR Electric Company, Inc., we create process skids for industrial businesses of all kinds. Our industrial engineers are knowledgeable and experienced in process skid development. They will work with you to discuss your requirements and build a skid that meets your needs. Your custom process skid will help to streamline your process and have a direct impact on your productivity. Contact us today to learn more about how process skids can benefit your business!